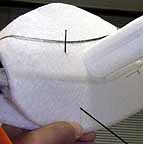

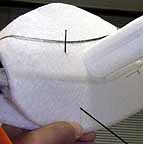

The smaller Nichrome line cutter was made to accessories logging.

A battery is Ni-cad 4 cell for receivers.

The cypress stick was made the guide, EPP was sliced thinly, and board

material (4mm and 3mm) was started.

Manufacture of the main wings

The paper pattern was made by plastic van and the rib was cut down

from 3mm thick EPP.

The board for Planck is also 3mm thick EPP. Ruler was put and bent

and the peculiarity is attached.

Spa is also 3mm thick EPP.

Each GP

clearance of the Konishi bond It comes out and pastes up.

The aluminum angle was used and it acted at a stretch as Planck of

the upper surface.

Since it is a soft material, mind is used very well so that it may

not be distorted.

Pie was closed like a Chinese meat dumpling and pasted up.

1mm carbon rod was embedded at the upper and lower sides for the central

part, and all circumferences were reinforced on the glass tape.

The weight of wings is only 25.4g.

Don't you stick a film, either and can do so lightly that it is not

believed that it is this method?

Manufacture of the body

4mm thick EPP is cut as the drawing which carried out the expansion

copy.

Reinforcement is stood to a part for the central part by 4mm thick

EPP.

Linkage for horizontal stabilizers is carried out.

Servo was pasted up by the double-sided tape and GP clearance.

The phon attached to the shaft processes the phon for Servo .

It is for motor mount to an EPP block.

While turning pushing and a hole are made for the carbon pipe

of 10mm of diameters of inner.

Wings were inserted in the body and right and left were pasted up.

The Servo code for an elevator and rudders extends.

Aileron servo made the hole in the main wings undersurface, and pasted

it.

The upper and lower sides are closed by GP clearance, taking care so

that the body may not be distorted.

A canopy portion is not pasted up.

The piece of Velcro was cut down thinly and stuck on the canopy portion.

The battery exchange method which reverses the

common sense of an EPP no one but!

Piece of Velcro and a piece of Velcro are removed and an inside

is accessed.

Triangular material was pasted up on the nose of an airplane.

A motor is inserted in the carbon pipe of a nose of an airplane.

It attaches by point attachment of a tie lap and Super-X.

ERURON hinge

The thing which put a part of adhesion side of a glass tape together

is prepared.

It decided to stick alternately and to make it an Aileron hinge.

It starts by 6mm thick EPP, and Aileron is the sake of twist prevention.

Spray paste is played and the film is stuck.

A little Angle of the body was rounded. The place seen from the undersurface.

Manufacture of a horizontal

stabilizer

A horizontal stabilizer is also the rib group structure of 3mm thick

EPP. It combines by GP clearance.

The hole is made so that a carbon pipe may enter.

Aileron servo is under wings.

Two servo is buried with the tail.

The phon for rudders is what was made from the video case at the time

of No. 1.

The axle hole of a horizontal stabilizer is the clear file bought at

the shop. [ of 100 yen ]

It starts and makes from a cover.

A horizontal stabilizer is inserted in a pipe and it pastes up. Adhesives

are Supermarkets X.

The glass tape is stuck on four corners for reinforcement of the body.

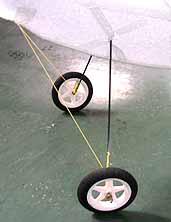

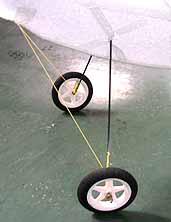

Manufacture of a leg

The carbon rod is thrust into legs at the body.

Adhesives are Supermarkets X.

Piano wire is connected with thread at the tip of a rod, and a wheel

is attached.

EPP of the portion which has attached the leg does not split -- as

The character of ‚ was reinforced combining the glass tape.

Moreover, even when it thrust in from the front, the tension line was

attached so that a carbon rod might not break.

Tail Skid attaches 1mm carbon rod on a glass tape.

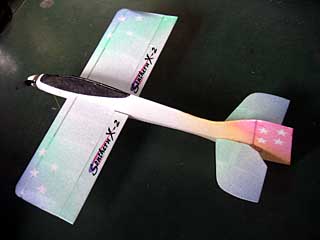

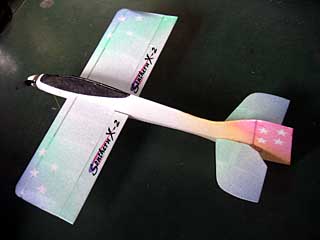

Completion!

Urethane was blown lightly and painted.

The increase in weight by paint is about 3g.

It became a quite large-patterned body. If only size is seen, is it

the same level as 540 classes?

But it is overly as lightweight as 280g at a battery lump.

It is such if an inside is opened.

The sticker was made with the personal computer.

The maximum angle of a rudder 45 degrees or more.

It seems to be more in good condition for PJS550 motor to reduce a

rotation angle.

The place which reduced and adjusted iŠp of a motor by setup of a

phoenix controller,

Current when balancing with prudence, What

and 3A !

Although it thinks that lightweight-ization of the body is also effective,

they will be what and an efficient motor.

I have already been moved to tears... (ToT )

- flown early -- it is -- !

NEW!

Flight in PURESSHON

Are surprised first at the moment of flying,

They are lightweight-izing of the body, and a sharp response by the

high power motor.

A top [ throttle / half ] hardly uses even the time of hovering.

Since it can escape to the sky immediately even if it is practicing

and a posture collapses

feeling easy -- a low altitude -- hovering -- it can practice -- having

come .

However, lightweight-ization is not a good language loan.

It is hard to give the too light cause and cobra.

He has a feeling that the range of hovering is very narrow to level

flight.

Moreover, performance using inertia is difficult for

the extremely light airplane of a load on wings.

But this is unavoidable ... (^_^;)

It is the body which is very easy to do a knife edge.

Does it seem that an upper side product is large since it turns only

at a few to a rise side?

I think that it will cut later and will adjust.

Even if it falls, it is a stake breaking very much, and it is sushi.

Even if it repeats hovering, a 20-minute or more flight with one battery

is possible.

Is it the optimal body for a fan fly beginner?

If Economy flight , probably it will be earnest, and is flying 30 minutes

or more easy? o(^-^)o

Further improvement

I improved effectiveness of a rudder.

The angle of a rudder was increased and the counter portion was attached.

Since the leg of carbon broke when it fell, piano wire was constructed

and remade.

It sticks on the body on a glass tape.

Since he wanted to use APC-SF Pella more efficient than chip box Pella

Propeller

SEBA is made himself by the adapter of QRP. It carried out.

Since it turns out that a motor takes and •t slackens on a tie lap

It was made for a hose band to fasten firmly.

A board is cut down from the tray made from polypropylene for reinforcement

of a mount portion.

It stopped on the glass tape. (Adhesion is nothing.)

Only tape.

It did not paste up but the body and the carbon pipe are hooked on

the glass tape.

It is "the theory which ‚¯ the thing which

has not been pasted up and does not separate." . (Smile)

However it may fall, it does not break probably.

SouthernX2 for simulators

The

body for FMS is here. SouthernX2.zip 73kb